Vacuum Casting Materials

You have a variety of options for vacuum molding materials based on your project's specific requirements. These resins are usually substitutes for usual plastic materials with similar performance and look. We've categorized our urethane casting materials into general groups to assist you in making optimal choices for your project.

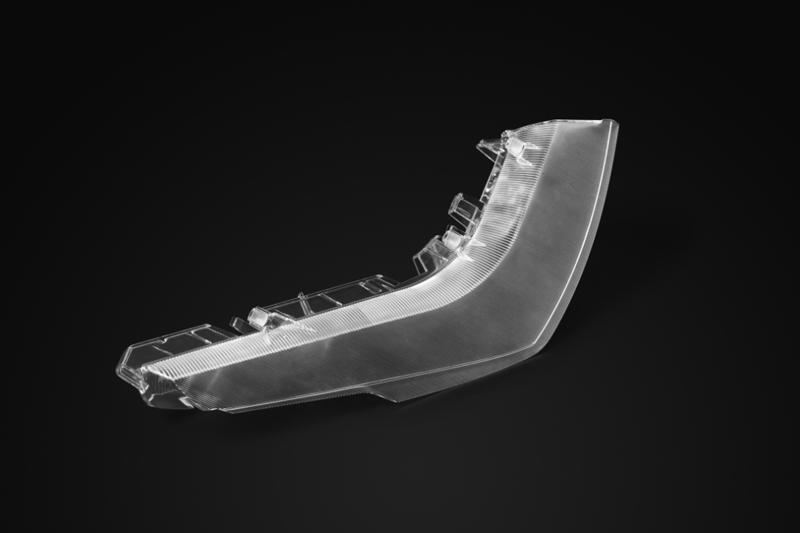

PMMA

Surface Finish for Vacuum Casted Parts

Breton Precision can produce distinct surface layers for your vacuum casting parts using a wide range of surface finishes. These options aid in fulfilling the visual, toughness, and chemical protection needs of your products. We can provide different surface finishes based on your material choice and part usage.

|

|

Available Finishing |

Description |

SPI Standard |

Link |

|

|

High Gloss |

A highly mirrored effect is achieved by polishing the master model prior to mold production. This lustrous finish provides excellent clarity, making it ideal for aesthetic components, optics, and other surfaces that can be easily cleaned. |

A1, A2, A3 |

|

|

Semi Gloss |

This B quality finish does not have a strong reflection, but it does provide a little luster. By employing coarse sandpaper, you can achieve sleek, washable surfaces that fall between high-gloss and matte. |

B1, B2, B3 |

|

|

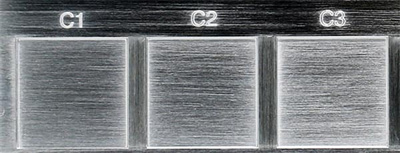

Matte Finish |

The satin finish of vacuum-molded components is achieved by bead or sandblasting the original pattern. C-quality surface treatments work well for areas requiring frequent contact and for handheld parts. |

C1, C2, C3 |

|

|

Custom |

RapidDirect may also offer personalized finishes using extra methods. Upon request, you may receive exceptional secondary finishes for optimum outcomes. |

D1, D2, D3 |

Vacuum Casting Tolerances

Breton Precision presents various tolerance options for vacuum molding to fulfill your specific needs. With the master model and component shape as reference, we can achieve dimensional precision within the range of 0.2 – 0.4 m. Following are the technical details of our vacuum molding offerings.

Type |

Information |

Accuracy |

Highest precision to reach ±0.05 mm |

Max Part Size |

+/- 0.025 mm +/- 0.001 inch |

Minimum wall thickness |

1.5mm~2.5mm |

Quantities |

20-25 copies per mold |

Color & Finishing |

Color and texture can be customized |

Typical Lead Time |

Up to 20 parts in 15 days or less |