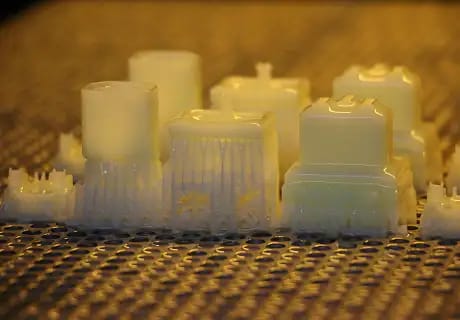

Breton Precision Rapid Prototyping and On-Demand Production for

Medical Device Industry

New product development for the medical industry with on demand manufacturing. From rapid prototyping to mass production of medical products, enjoy reliable manufacturing services at competitive pricing.

● High precision medical products

● ISO 9001:2015 certiified

● 24/7 engineering support

Thermoplastics

Thermoplastics are highly durable, flexible, and functional materials for medical product manufacturing. They have excellent corrosion, detergent and chemical resistance, making them last longer than other typical medical materials. Thermoplastics are also very adhesive to metals, making them useful for overmolding medical prototypes for improved functionality.

Our extensive production capabilities allow us to improve medical device production to serve many healthcare applications. Some of the applications include:

● Handheld devices

● Surgical instruments

● Medical testing devices

● Medical delivery systems

● Ventilators

● Implantable prototypes

● Prosthetic components

● Microfluidics

● UV sanitation components