Vacuum Casting Materials

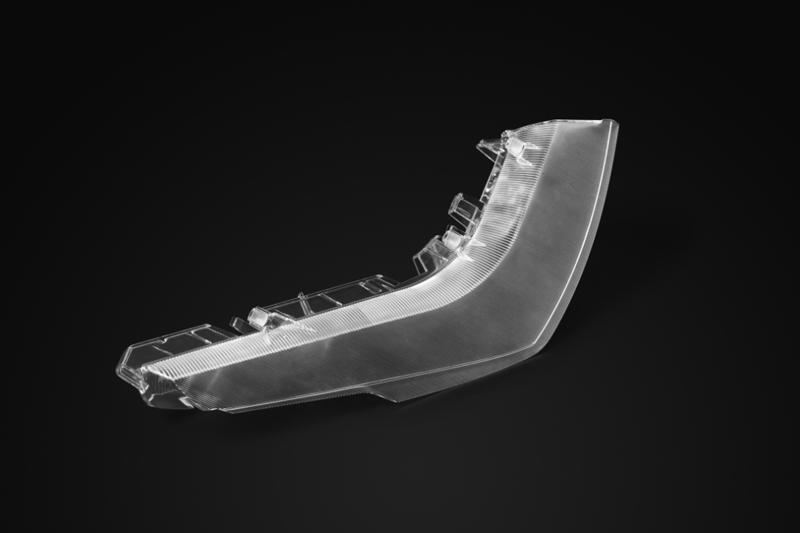

You have the option to select from a diverse assortment of vacuum infusion components based on the specifics of your undertaking. These polymers generally imitate everyday plastic materials with similar performance and visual characteristics. Our urethane casting materials have been categorized broadly to aid in the optimization of the most suitable choices for your project.

Polycarbonate-Like

Surface Finish for Vacuum Casted Parts

Utilizing a wide range of surface textures, Breton Precision is able to produce distinctive outer layers for your vacuum molded components. These textures can assist in fulfilling the visual appeal, toughness, and chemical resilience criteria for your items. Upon assessing your material choices and the uses of your components, we are able to provide a range of surface textures.

|

|

Available Finishing |

Description |

SPI Standard |

Link |

|

|

High Gloss |

Extremely gleaming surface polish attained via perfecting the original template ahead of producing the mold. The lustrous finish provides remarkable clarity effective for aesthetic components, optical devices, and additional surfaces that can be sanitized. |

A1, A2, A3 |

|

|

Semi Gloss |

This grade B finish doesn't reflect light a lot but provides a slight luster. By using coarse sandpaper, you can achieve surfaces that are cleanable and smooth, falling between high-gloss and matte. |

B1, B2, B3 |

|

|

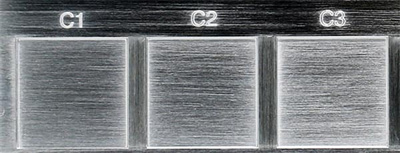

Matte Finish |

The satin finish of vacuum cast parts is achieved by bead or sandblasting the original model. C-grade finishes work well in touch-intensive zones and for handheld parts. |

C1, C2, C3 |

|

|

Custom |

RapidDirect can also provide custom finishes through additional processes. On request, you can get unique secondary finishes for the best results. |

D1, D2, D3 |

Vacuum Casting Tolerances

Breton Precision provides a variety of casting tolerances to match your specific needs. By using the original model and component shape, we can achieve dimensional tolerances from 0.2 to 0.4 meters. The following are the technical details for our casting services.

Type |

Information |

Accuracy |

Highest precision to reach ±0.05 mm |

Max Part Size |

+/- 0.025 mm +/- 0.001 inch |

Minimum wall thickness |

1.5mm~2.5mm |

Quantities |

20-25 copies per mold |

Color & Finishing |

Color and texture can be customized |

Typical Lead Time |

Up to 20 parts in 15 days or less |