Vacuum Casting Materials

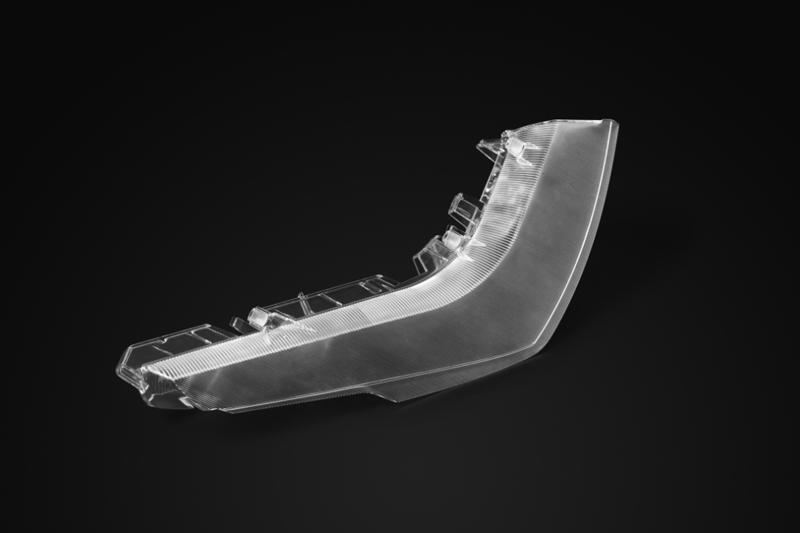

You have the option to select from a diverse array of materials for vacuum casting to match the specifics of your project. Generally, these resins mimic common plastic materials in terms of performance and appearance. Our urethane casting materials are classified to support your decision-making process for your project.

Acrylic-Like

Surface Finish for Vacuum Casted Parts

Offering a wide range of surface textures, Breton Precision is able to produce distinct surface coatings for your vacuum cast parts. These coatings aid in fulfilling the look, strength, and chemical resilience needs of your products. Based on the materials and uses of your parts, we can provide the subsequent surface textures:

|

|

Available Finishing |

Description |

SPI Standard |

Link |

|

|

High Gloss |

The master pattern is polished to create a highly reflective surface finish before making the mold. The glossy finish provides excellent transparency and is beneficial for cosmetic parts, lenses, and various cleanable surfaces. |

A1, A2, A3 |

|

|

Semi Gloss |

The B rank finish lacks high reflectivity yet has some luster. By employing rough sandpaper, you can achieve sleek, washable areas falling between high-shine and dull. |

B1, B2, B3 |

|

|

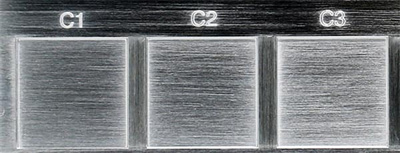

Matte Finish |

Vacuum molding pieces acquire a smooth, silky appearance from the abrasive or sandblasting of the initial model. The C-level coatings are well-suited for surfaces frequently contacted and portable parts. |

C1, C2, C3 |

|

|

Custom |

RapidDirect is also able to provide tailor-made coatings using supplementary techniques. If desired, you are able to procure distinctive secondary coatings for optimal outcomes. |

D1, D2, D3 |

Vacuum Casting Tolerances

Breton Precision provides various vacuum molding tolerances to fulfill your specific needs. With the help of the model and component shape, we are capable of achieving size allowances ranging from 0.2 to 0.4 meters. The following are the detailed specifications for our vacuum molding services.

Type |

Information |

Accuracy |

Highest precision to reach ±0.05 mm |

Max Part Size |

+/- 0.025 mm +/- 0.001 inch |

Minimum wall thickness |

1.5mm~2.5mm |

Quantities |

20-25 copies per mold |

Color & Finishing |

Color and texture can be customized |

Typical Lead Time |

Up to 20 parts in 15 days or less |