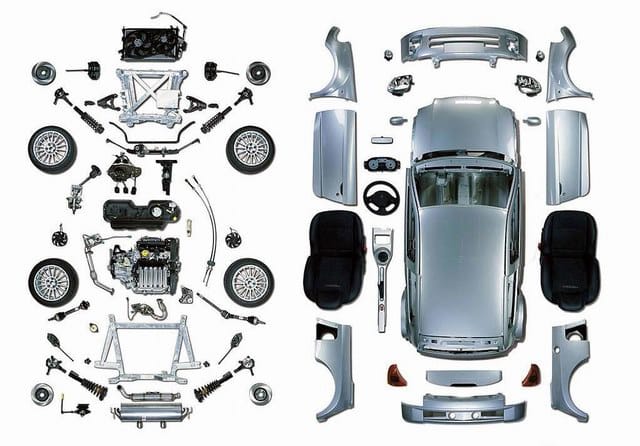

Breton Precision Rapid Prototyping and On-Demand Production for

Automotive Industry

Custom automotive prototyping and parts manufacturing services for automotive product development. Streamlined manufacturing processes, competitive prices, and on-demand production.

● Tolerances down to ±0.0004″ (0.01mm)

● ISO 9001:2015 certiified

● 24/7 engineering support

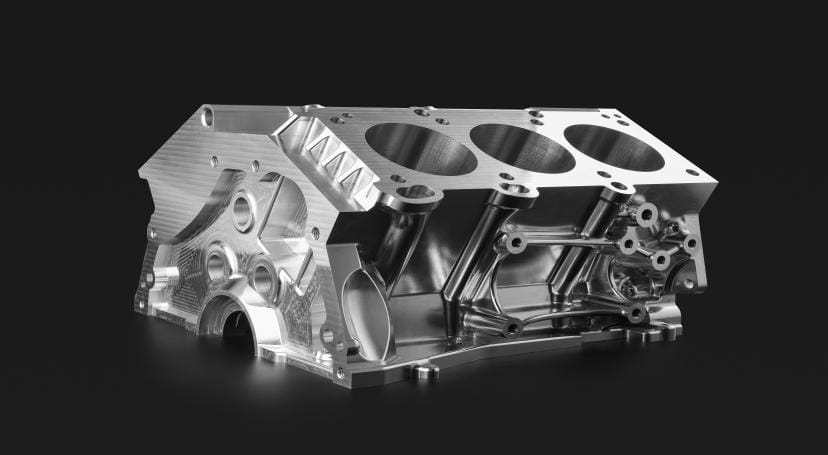

Aluminum

Aluminum has an excellent strength-to-weight ratio, making it ideal for producing lightweight automotive parts. This metal has several beneficial properties, including stiffness, corrosion resistance, ductility, and high machinability. Aluminum is ideal for making engine blocks, intake manifolds, lamps, wheels, cylinder heads, etc.

Price: $

Lead Time: < 10 days

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

At Breton Precision, we improve the production rate of a wide range of automotive components. Common automotive applications we undertake include.

● Lighting features and lenses

● Aftermarket parts

● Fixtures

● Housing and enclosures

● Armatures

● Assembly line components

● Support for vehicular consumer electronics

● Plastic dash components