Vacuum Casting Materials

You can select from a wide variety of materials for vacuum casting according to your project's specific requirements. These resins usually mimic typical plastic materials with similar performance and look. Our urethane casting materials are classified into broad categories to assist you in making optimal project decisions.

Elastomer

Surface Finish for Vacuum Casted Parts

Breton Precision offers a wide range of surface textures for your vacuum molded components. These textures support your items' visual, toughness, and chemical resistance standards. We have various surface textures available based on your material choices and component uses.

|

|

Available Finishing |

Description |

SPI Standard |

Link |

|

|

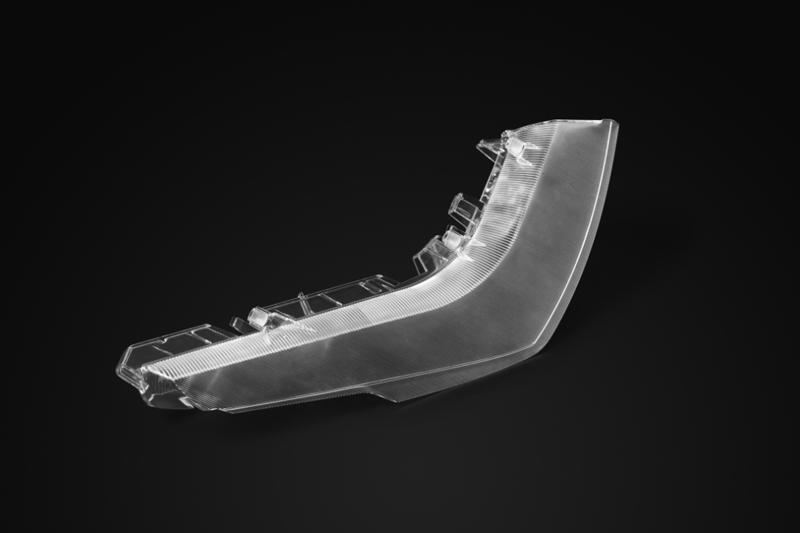

High Gloss |

The master pattern is polished to create a reflective finish for mold making. This shiny finish is beneficial for cosmetic parts, lenses, and cleanable surfaces due to its transparency. |

A1, A2, A3 |

|

|

Semi Gloss |

This B-level finish is not very shiny but provides some luster. By utilizing coarse sandpaper, you can achieve sleek, washable areas between glossy and flat. |

B1, B2, B3 |

|

|

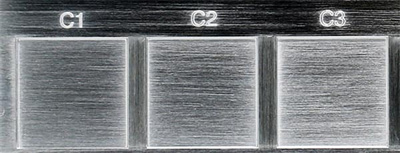

Matte Finish |

The satin finish on vacuum-cast parts will be achieved by bead or sand blasting the original template. This C-level finish is well-suited for hands-on and handheld parts. |

C1, C2, C3 |

|

|

Custom |

RapidDirect can also offer personalized finishes via supplementary procedures. If desired, you may obtain distinctive secondary finishes to optimize outcomes. |

D1, D2, D3 |

Vacuum Casting Tolerances

Breton Accuracy presents an array of vacuum casting acceptance levels to fulfill your specific demands. Using the original pattern and component shape, we can achieve dimension approval between 0.2 to 0.4 m. Here are the detailed standards for our vacuum casting amenities.

Type |

Information |

Accuracy |

Highest precision to reach ±0.05 mm |

Max Part Size |

+/- 0.025 mm +/- 0.001 inch |

Minimum wall thickness |

1.5mm~2.5mm |

Quantities |

20-25 copies per mold |

Color & Finishing |

Color and texture can be customized |

Typical Lead Time |

Up to 20 parts in 15 days or less |