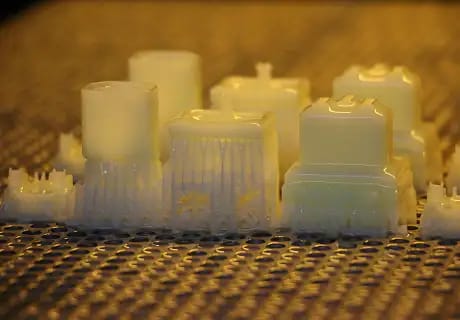

Breton Precision Rapid Prototyping and On-Demand Production for

Aerospace Industry

Get high-quality manufacturing services for your custom aerospace prototypes and production parts. Launch products faster, reduce risks, and streamline production processes with on-demand production at competitive prices.

● Production-grade products

● ISO 9001:2015 certiified

● 24/7 engineering support

Aluminum

Aluminum has an excellent strength-to-weight ratio of this metal. It is a great option for the high loading requirements of aircraft brackets and housings. Aluminum also boasts good ductility, stiffness, corrosion resistance, and machinability. Its lightweight properties make it useful for aerospace structural applications like fuselage skin, wing stringers, wing skins, etc.

Price: $

Lead Time: < 10 days

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

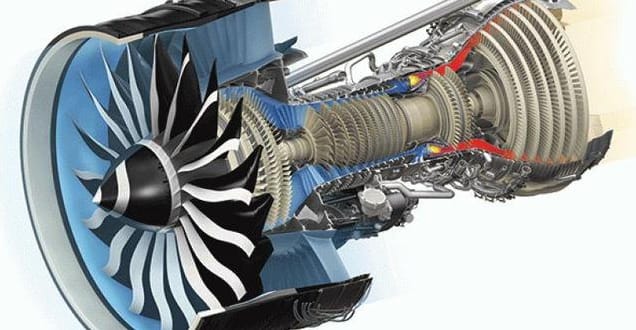

Our manufacturing capabilities help accelerate the production of a wide range of aerospace components for unique applications. Here are some of the common aerospace applications:

● Rapid tooling, brackets, chassis, and jigs

● Heat exchangers

● Custom fixturing

● Conformal cooling channels

● Turbo pumps and manifolds

● Fit check gauges

● Fuel nozzles

● Gas and liquid flow components