0102030405

Many of our dresses feature beautiful beading on the sleeves

2018-07-16

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

Lorm Ipsum has been the industry's standard

dummy text took a galley of type and scrambed it to make a type specimen

book. Lorem Ipsum is simply dummy text of the

printing and typesetting Lorem Ipsum is simply dummy text of the printing

and typesetting industry.Lorem Ipsum is simply

dummy text of the printing and typesetting industry.

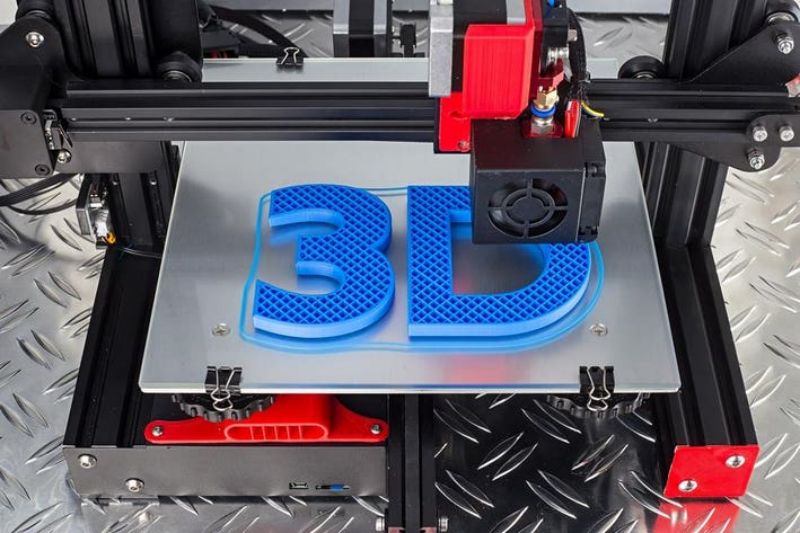

Welcome to the captivating realm of CNC machining, where innovation meets precision! In today's blog, we delve into the fascinating world of Computer Numerical Control (CNC) machining, a revolutionary manufacturing process that has transformed various industries. From the automotive and aerospace sectors to medical and consumer electronics industries, CNC machining has proven to be a game-changer, ensuring both unparalleled accuracy and efficiency. So, let's embark on this enlightening journey and explore the incredible capabilities and impact of CNC machining.

Understanding CNC Machining:

CNC machining involves the use of computer-controlled machines to perform intricate tasks that were once considered labor-intensive and time-consuming. Through precise instructions encoded in a software program, CNC machines can meticulously shape and manipulate raw materials such as metal, plastic, wood, and even advanced composites. This automated process brings consistency, reliability, and an unprecedented level of precision to manufacturing processes, eliminating human errors and enhancing overall productivity.

Unleashing Creativity and Complexity:

With CNC machining, manufacturers can effortlessly transform complex designs into tangible products. By leveraging Computer-Aided Design (CAD) software, intricate shapes and geometries can be effortlessly translated into CNC machine instructions. Whether it's crafting intricate automotive engine components or sculpting artistic masterpieces, CNC machining provides endless possibilities for realizing precise and intricate designs, bringing even the most imaginative concepts to life.

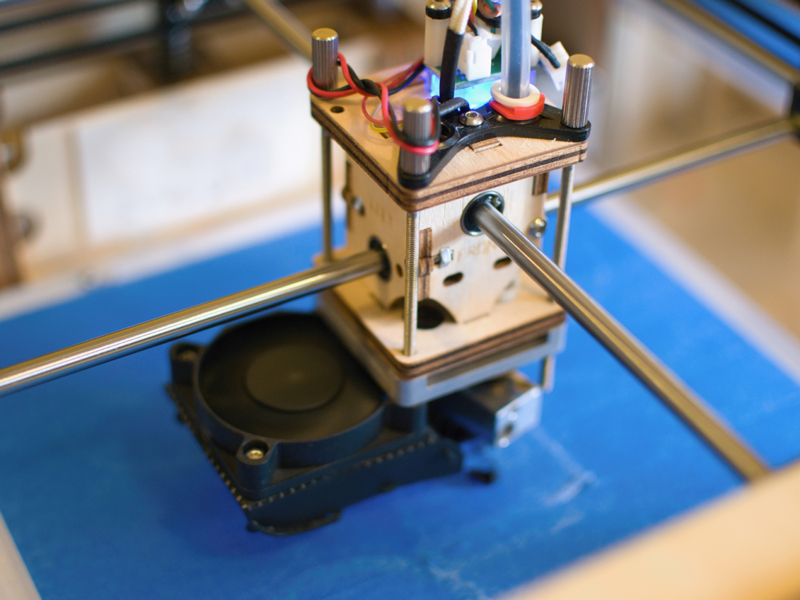

The Trifecta of Accuracy, Speed, and Consistency:

One of the key reasons CNC machining has become the gold standard in manufacturing is its unmatched accuracy. CNC machines can achieve intricate measurements with microscopic precision, ensuring each product/component adheres to strict tolerances. This level of precision significantly minimizes the likelihood of defects, thereby reducing material wastage and maximizing the efficiency of the manufacturing process.

Additionally, CNC machines operate at incredible speeds without compromising on accuracy. This allows manufacturers to meet demanding production deadlines while maintaining impeccable quality. Alongside speed and accuracy, CNC machines deliver exceptional consistency, ensuring that each piece produced adheres precisely to the design specifications, even over prolonged periods of production.

Enhancing Efficiency and Cost-effectiveness:

The intelligent automation offered by CNC machining has revolutionized industrial production and made it remarkably efficient. By eliminating the need for manual labor in many manufacturing processes, CNC machines free up human resources for other complex tasks that require creativity and critical thinking. Moreover, CNC machining drastically reduces the need for extensive manual supervision, leading to cost savings and increased productivity.

Moreover, CNC machining reduces material wastage by optimizing material utilization. With precise cutting methods, CNC machines minimize raw material losses, contributing to a sustainable and environmentally friendly approach to manufacturing.

Expanding the Possibilities:

CNC machining's versatility extends across industries, including automotive, aerospace, medical, electronics, and beyond. In the healthcare sector, CNC machines play a vital role in producing medical devices, prosthetics, and surgical instruments with unparalleled precision. The aerospace industry relies on CNC machining for manufacturing complex aircraft components to ensure exceptional strength and reliability. CNC machines also aid in the production of electronic components, enabling the miniaturization of devices and enhancing overall performance.

Conclusion:

CNC machining has undoubtedly reshaped the manufacturing landscape, revolutionizing precision manufacturing and propelling industries forward. The amalgamation of precision, speed, consistency, and cost-effectiveness that CNC machining offers has undoubtedly made it an indispensable tool in modern manufacturing. As technology advances and its applications expand, the possibilities of CNC machining are limitless, propelling industries into new dimensions of excellence, innovation, and efficiency.