0102030405

Many of our dresses feature beautiful beading on the sleeves

2018-07-16

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

Lorm Ipsum has been the industry's standard

dummy text took a galley of type and scrambed it to make a type specimen

book. Lorem Ipsum is simply dummy text of the

printing and typesetting Lorem Ipsum is simply dummy text of the printing

and typesetting industry.Lorem Ipsum is simply

dummy text of the printing and typesetting industry.

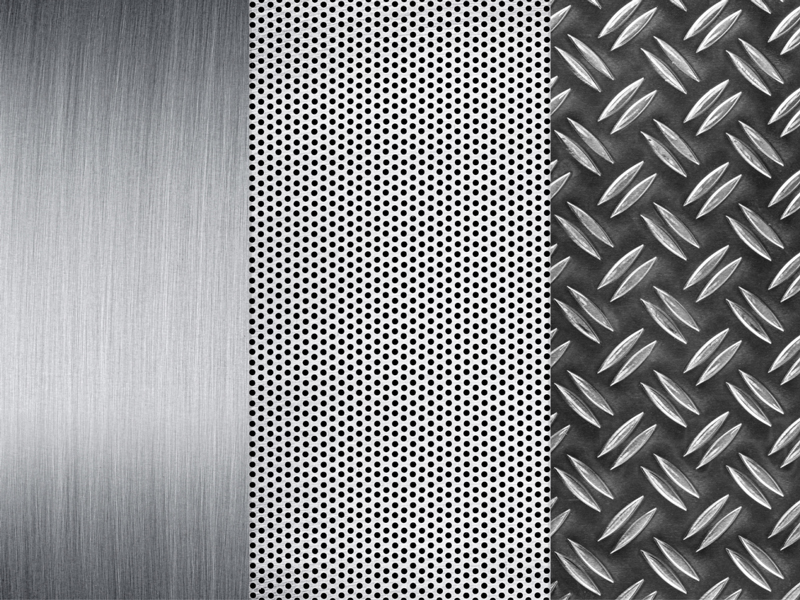

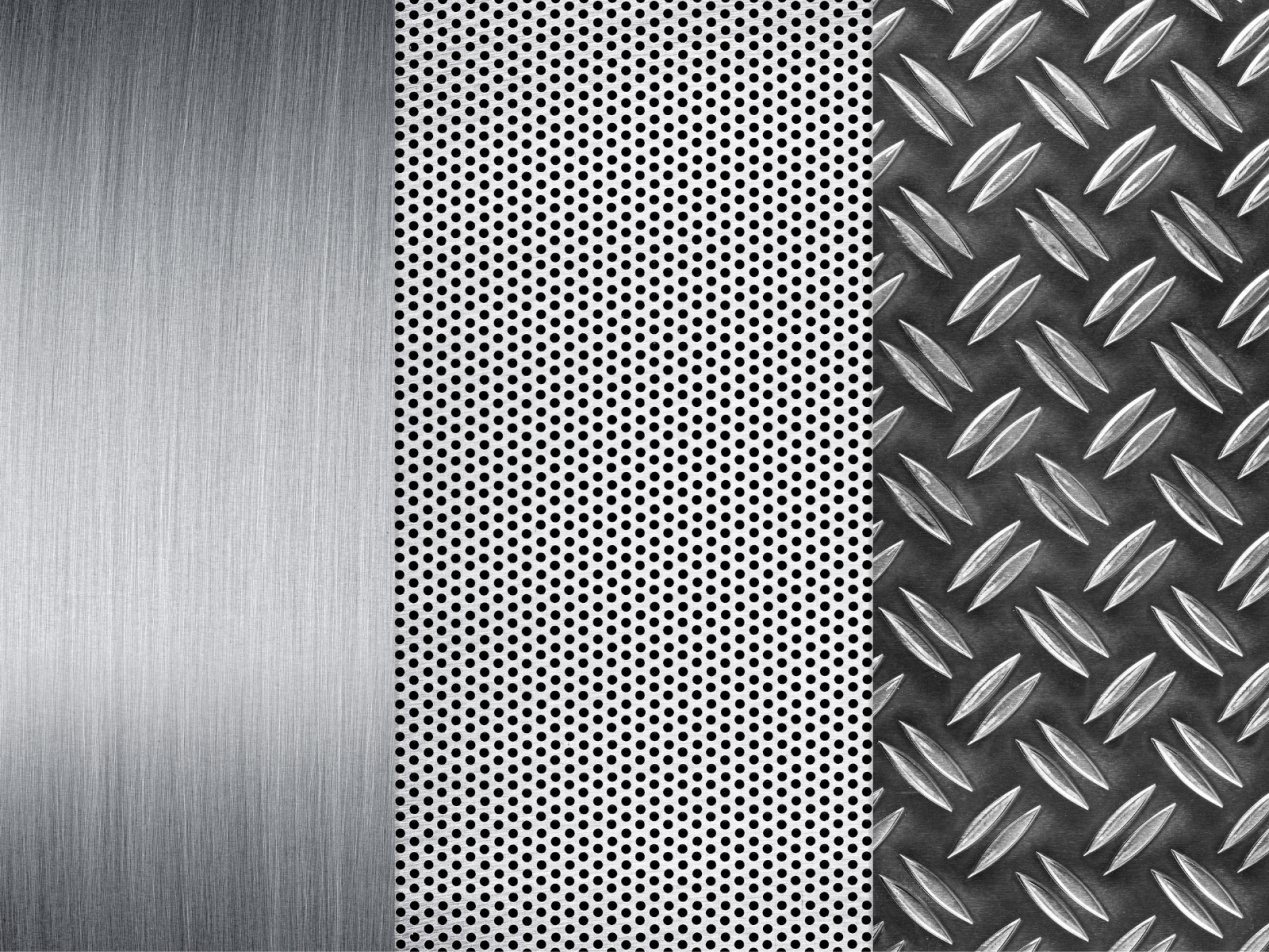

In the world of manufacturing, sheet metal holds a significant place due to its unparalleled versatility and numerous advantages. Whether it is for fabrication, construction, or various industrial applications, sheet metal offers an array of benefits that have revolutionized modern manufacturing processes. In this blog, we will delve into the fascinating world of sheet metal, exploring its versatility, applications, advantages, and the role it plays in shaping our everyday lives.

Unleashing the Versatility of Sheet Metal:

Sheet metal, a flat and thin piece of metal, comes in various forms, including stainless steel, aluminum, brass, and copper. Its remarkable versatility lends itself to a myriad of applications across diverse industries. One of the primary reasons behind its widespread usage is its ability to be custom-shaped based on specific requirements. Manufacturers can easily cut, mold, stamp, and bend sheet metal to create intricate shapes and designs, making it a popular choice in automotive, aerospace, and architectural industries, among others.

Applications Galore:

The use of sheet metal extends beyond what meets the eye. From household items to complex machinery components, here are some noteworthy applications:

1. Automotive Industry: Sheet metal forms the backbone of the automotive industry, playing a crucial role in manufacturing car bodies, chassis, panels, and frames. It provides durability, corrosion resistance, and allows for lightweight design, leading to improved fuel efficiency.

2. Construction and Architecture: Sheet metal finds extensive use in construction, contributing to structures such as roofs, gutters, window frames, and ventilation systems. Its strength, durability, and weather resistance make it an ideal choice for architects and construction professionals.

3. Industrial Machinery: Sheet metal is employed in the production of machinery components, such as enclosures, cabinets, and frames. Its ability to withstand various environmental conditions, coupled with its durability, ensures optimal performance in harsh industrial settings.

Advantages of Sheet Metal:

1. Strength and Durability: Sheet metal possesses exceptional strength and durability, capable of withstanding extreme temperatures, pressure, and wear. This attribute makes it ideal for high-performance applications where structural integrity is paramount.

2. Cost-Effectiveness: Sheet metal fabrication offers a cost-effective solution compared to other manufacturing methods. Its abundant availability, minimal material waste during production, and ease of customization contribute to its cost efficiency.

3. Aesthetic Appeal and Finishing Options: Sheet metal allows for versatile finishes, enhancing both functionality and aesthetic appeal. By adding various coatings, paints, or finishes, manufacturers can achieve desired visual effects while ensuring protection against corrosion.

Conclusion:

As demonstrated, sheet metal’s versatility and advantages have transformed the manufacturing landscape, contributing to various industries and everyday products that we rely on. From its customizability to its cost-effectiveness, strength, and durability, sheet metal’s remarkable qualities make it an essential material in architecture, automotive, and industrial sectors alike.

Innovation continues to fuel new advancements in sheet metal fabrication techniques, further broadening its applications. As we embrace the possibilities brought forth by emerging technologies, sheet metal will continue to stand tall as a vital component in shaping the modern world we live in.