From Concept To Creation: The Role Of 3D Printing In Product Development

2024-04-10 09:15:22

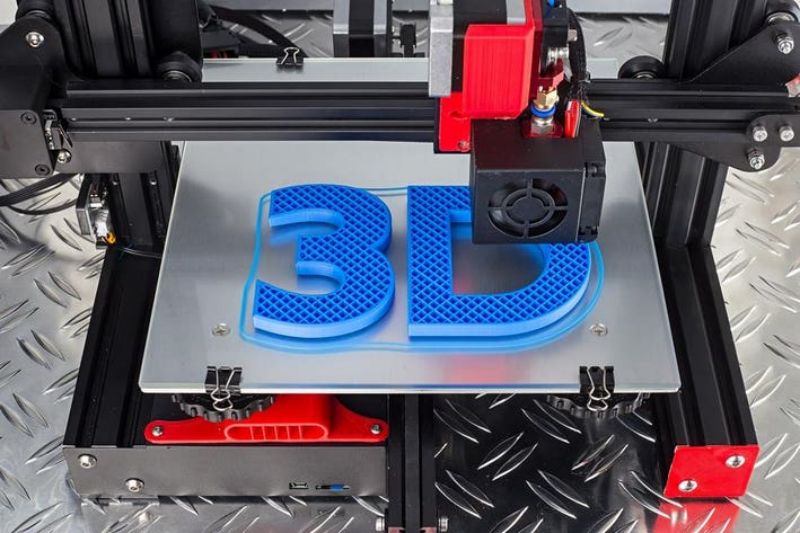

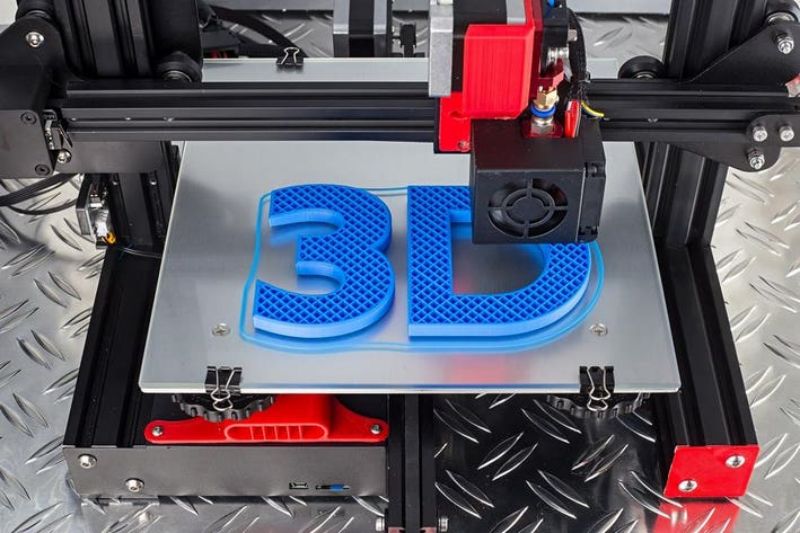

What is 3D Printing?

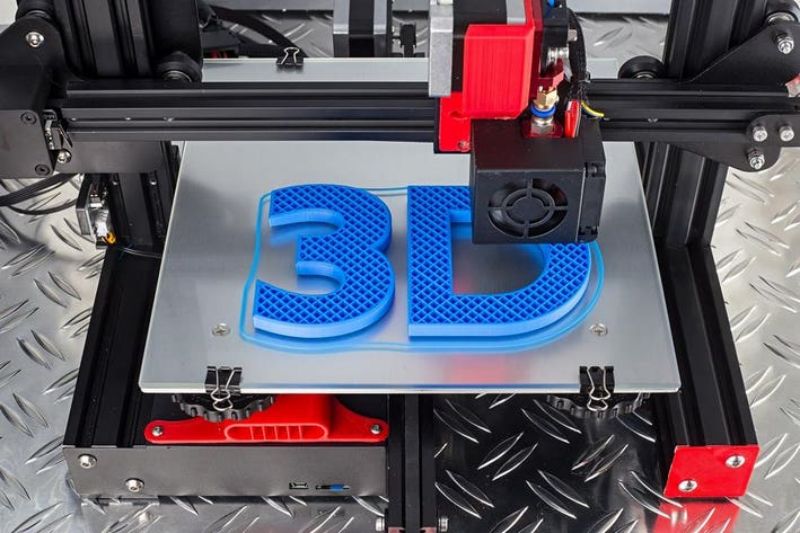

3D printing is a manufacturing process that involves creating physical objects from digital designs. It uses a layer-by-layer approach, where materials are added one layer at a time until the final product is formed. This technology has been around for over three decades but has recently gained significant popularity due to its accessibility and affordability.

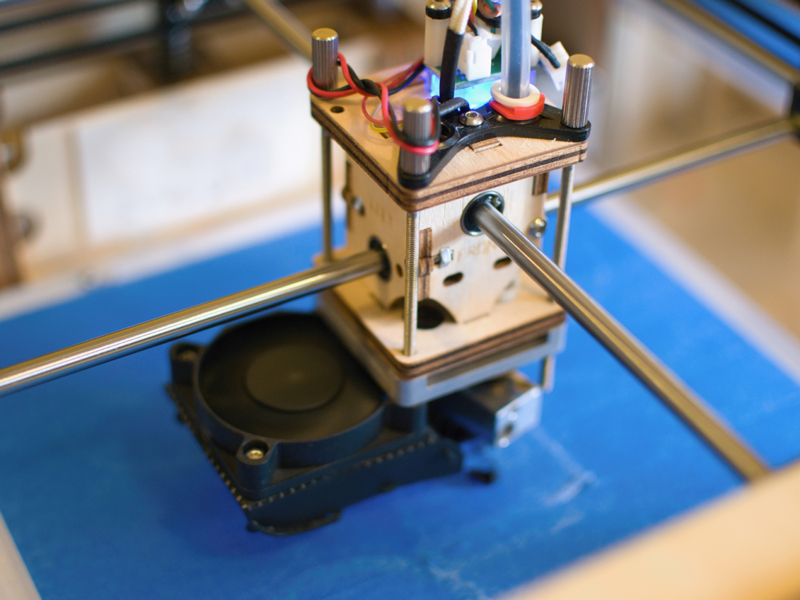

The process of 3D printing starts with creating a digital design using Computer-Aided Design (CAD) software or 3D scanning technology. This digital file is then sent to a 3D printer, which reads the instructions and begins the printing process. Depending on the material used, the printer will either melt, cure, or bind layers of material together to create a solid object.

There are several types of 3D printing technologies, each with its unique set of advantages and limitations. Some popular methods include Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). These techniques differ in the materials used, printing speed, and level of detail they can achieve.

3D printing is not limited to a specific type of material; it can work with plastics, metals, ceramics, and even human tissue. This versatility makes it an incredibly valuable tool in product development as it allows for the creation of complex and functional prototypes.

Benefits of 3D Printing in Product Development

The introduction of 3D printing in product development has revolutionized the way products are designed, prototyped, and manufactured. Here are some of the key benefits that make it an essential tool for product development:

Rapid Prototyping: With traditional manufacturing methods, creating a prototype can take weeks or even months. 3D printing allows for the quick and cost-effective production of prototypes, allowing designers to test and refine their ideas in a matter of days.

Cost-Effective: 3D printing eliminates the need for expensive molds or tooling, making it a more cost-effective option for small-batch production runs. It also reduces material wastage, as only the required amount of material is used in the printing process.

Design Flexibility: The layer-by-layer approach of 3D printing allows for intricate and complex designs that would be impossible to achieve with traditional manufacturing methods. This flexibility enables designers to push the boundaries of creativity and innovation.

Faster Time to Market: With rapid prototyping and reduced lead times, 3D printing significantly speeds up the product development process, ultimately resulting in a faster time to market. This gives companies a competitive edge and allows them to stay ahead of their competition.

Customization: 3D printing makes it possible to produce custom products tailored to specific customer needs. This level of customization was previously difficult and expensive to achieve with traditional manufacturing methods.

Applications of 3D Printing in Product Development

The applications of 3D printing in product development are vast and varied, with new uses being discovered every day. Some of the most common applications include:

Prototyping: As mentioned earlier, rapid prototyping is one of the primary uses of 3D printing in product development. It allows designers to quickly iterate and refine their designs, resulting in better end products.

Functional Parts Production: 3D printing is also used for the production of functional parts that are used in final products. This includes components for machinery, electronics, and even medical devices.

Customized Consumer Products: With the rise of e-commerce and personalized products, 3D printing has become a popular method for producing customized consumer goods. Companies can now create unique and personalized products at scale, giving customers more options and control over their purchases.

Manufacturing Tools: 3D printing can also be used to produce manufacturing tools such as jigs, fixtures, and molds. This not only reduces lead times but also allows for the customization of these tools to meet specific production needs.

Medical Applications: 3D printing has made significant advancements in the medical field, allowing for the creation of custom prosthetics, implants, and even human tissue. It has also revolutionized surgical planning and training by creating accurate 3D models of patient anatomy.

Role Of 3D Printing In Transforming The Product Development Process

The integration of 3D printing in product development has transformed the traditional manufacturing process in several ways:

It has reduced the time and cost involved in producing prototypes and functional parts. This allows companies to quickly test and refine their ideas, resulting in better end products.

3D printing has opened up new design possibilities by allowing for the creation of complex and intricate designs that were previously difficult or impossible to manufacture using traditional methods. This has led to a wave of innovation and creativity in various industries.

With the ability to produce customized products at scale, 3D printing has also changed the relationship between businesses and consumers. Customers now have more control over their purchases, leading to increased satisfaction and loyalty.

The use of 3D printing in manufacturing tools and equipment has also improved efficiency and productivity in production processes. Customized jigs, fixtures, and molds allow for optimized production, reducing errors and improving overall quality.

Moreover, 3D printing has also had a significant impact on the medical field by making complex surgical procedures more accurate and reducing lead times in the production of medical devices. This has ultimately resulted in better patient outcomes and improved healthcare services.

Also the main advantage of 3D printing is that it allows for on-demand production, reducing the need for large inventories and minimizing the risk of overproduction. This leads to a more sustainable approach to manufacturing and reduces waste in the supply chain.