Sheet Metal Fabrication Materials

Our selection of sheet metal materials includes aluminum, brass, stainless steel, and copper, each enhancing the durability and aesthetics of your metal components.

Aluminum

Sheet Metal Fabrication Surface Finishing

Select from our various sheet metal finishes to enhance corrosion resistance, durability, and visual appeal. For finishes not listed on our quote page, simply select ‘Other’ and specify your requirements for a customized solution.

|

Name |

Materials |

Color |

Texture |

Thickness |

|

Anodizing |

Aluminum |

Clear, black, grey, red, blue, gold. |

Smooth, matte finish. |

A thin layer: 5-20 µm |

|

Bead Blasting |

Aluminum, Brass, Stainless Steel, Steel |

None |

Matte |

0.3mm-6mm |

|

Powder Coating |

Aluminum, Brass, Stainless Steel, Steel |

Black, any RAL code or Pantone number |

Gloss or semi-gloss |

5052 Aluminum 0.063″-0.500” |

|

Electroplating |

Aluminum, Brass, Stainless Steel, Steel |

Varies |

Smooth, glossy finish |

30-500 µin |

|

Polishing |

Aluminum, Brass, Stainless Steel, Steel |

N/A |

Glossy |

N/A |

|

Brushing |

Aluminum, Brass, Stainless Steel, Steel |

Varies |

Satin |

N/A |

|

Silkscreen Printing |

Aluminum, Brass, Stainless Steel, Steel |

Varies |

N/A |

< 1 µm |

|

Passivation |

Stainless Steel |

None |

Unchanged |

5μm – 25μm |

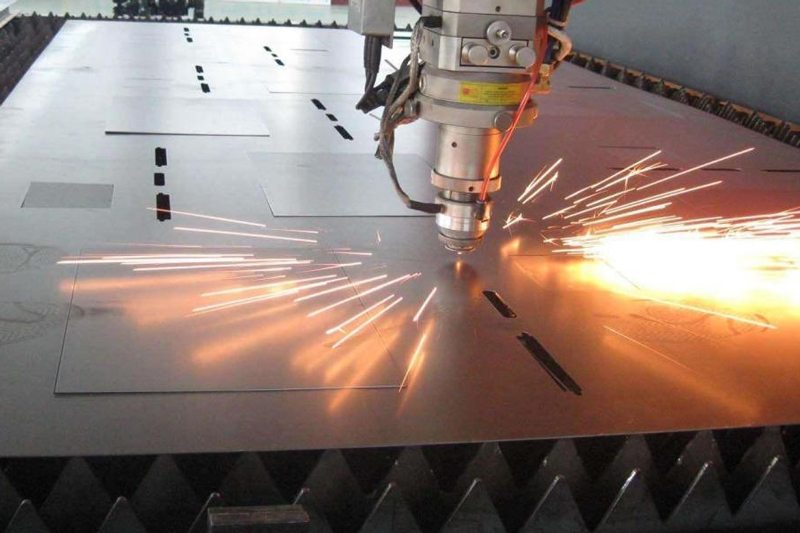

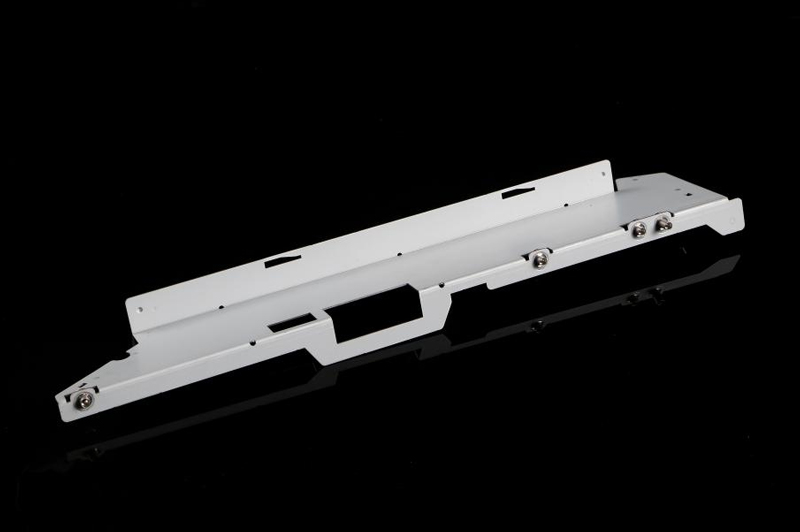

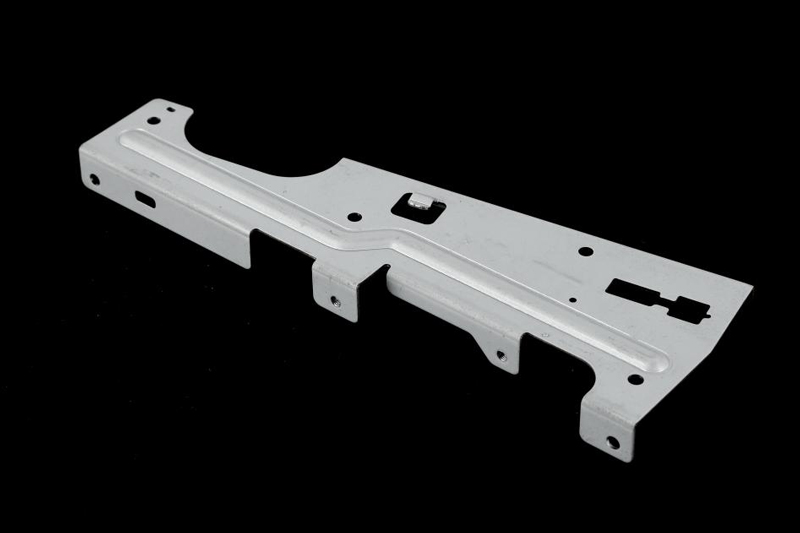

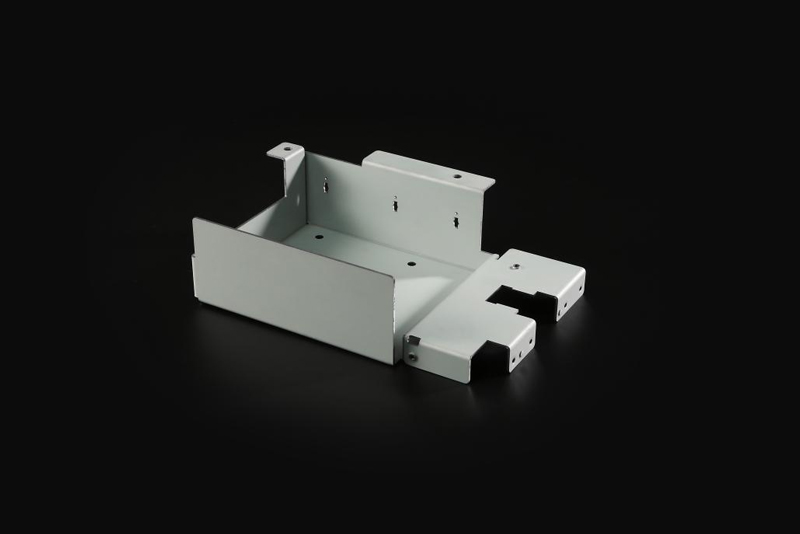

Breton Precision Sheet Metal Processes

Check out the specific advantages of each sheet metal techniques and find the perfect match when you order custom metal fabrication parts.

Process |

Techniques |

Precision |

Applications |

Material Thickness (MT) |

Lead Time |

Cutting |

Laser cutting, Plasma cutting |

+/- 0.1mm |

Stock material cutting |

6 mm (¼ inch) or less |

1-2 days |

Bending |

Bending |

Single bend: +/- 0.1mm |

Forming, pressing lines, imprinting characters, riveting of electrostatic guide rails, pressing grounding symbols, hole punching, pressing flat, pressing triangular reinforcements, and more. |

The smallest bend radius should be at least equal to the sheet thickness. |

1-2 days |

Welding |

Tig Welding, MIG welding, MAG welding, CO2 welding |

+/- 0.2mm |

For aircraft fuselages and engine components. In car bodies, exhaust systems, and chassis. In creating components for power generation and distribution systems. |

As low as 0.6 mm |

1-2 days |

General Tolerances for Sheet Metal Fabrication

Dimension Detail |

Metric Units |

Imperial Units |

Edge to edge, single surface |

+/- 0.127 mm |

+/- 0.005 in. |

Edge to hole, single surface |

+/- 0.127 mm |

+/- 0.005 in. |

Hole to hole, single surface |

+/- 0.127 mm |

+/- 0.005 in. |

Bend to edge / hole, single surface |

+/- 0.254 mm |

+/- 0.010 in. |

Edge to feature, multiple surface |

+/- 0.762 mm |

+/- 0.030 in. |

Over formed part, multiple surface |

+/- 0.762 mm |

+/- 0.030 in. |

Bend angle |

+/- 1° |

|

By default, sharp edges will be broken and deburred. For any critical edges that must be left sharp, please note and specify them in your drawing.