Vacuum Casting Materials

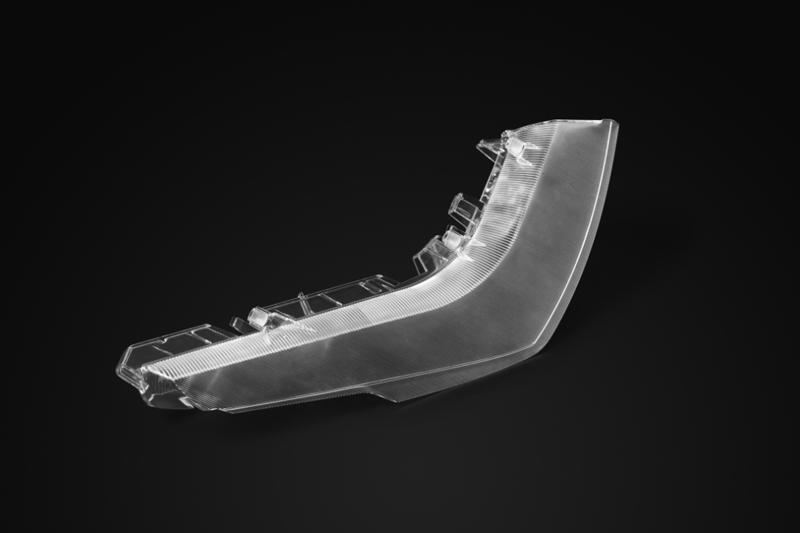

You have the option to select from a diverse selection of vacuum casting materials based on the unique aspects of your project. These polymers usually imitate traditional plastic materials with similar qualities and visual attributes. Our urethane casting materials have been classified into broad groupings to assist you in making optimal choices for your project.

Polypropylene-Like

Surface Finish for Vacuum Casted Parts

With an extensive array of surface finishes, Breton Precision can create unique surface layers for your vacuum casting parts. These finishes help you meet your products’ appearance, hardness, and chemical resistance requirements. Depending on your material selection and part applications, we can offer the following surface finishes:

|

|

Available Finishing |

Description |

SPI Standard |

Link |

|

|

High Gloss |

Surface finish with high reflectivity is produced by polishing the original pattern prior to making the mold. This glossy finish provides excellent translucency for parts intended for beauty, optics, and easily cleaned surfaces. |

A1, A2, A3 |

|

|

Semi Gloss |

This B level finish does not reflect light much but does provide a bit of shine. By employing coarse sandpaper, you can achieve smooth, washable surfaces that fall between glossy and flat. |

B1, B2, B3 |

|

|

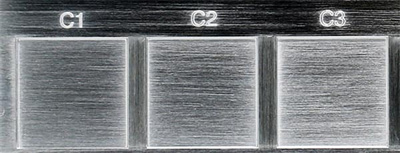

Matte Finish |

Cast parts from a vacuum will acquire a satin-like texture via bead or sand blasting of the original model. The C-quality finishes are perfect for components that are often touched and handheld. |

C1, C2, C3 |

|

|

Custom |

RapidDirect is able to offer tailored finishes using extra techniques. Upon demand, distinctive secondary finishes are accessible for optimal outcomes. |

D1, D2, D3 |

Vacuum Casting Tolerances

Breton Precision proposes various specifications of vacuum molding to fulfill your personalized needs. According to the initial design and component structure, we can achieve measurements ranging from 0.2 to 0.4 meters. The subsequent section provides details on our vacuum molding capabilities.

Type |

Information |

Accuracy |

Highest precision to reach ±0.05 mm |

Max Part Size |

+/- 0.025 mm +/- 0.001 inch |

Minimum wall thickness |

1.5mm~2.5mm |

Quantities |

20-25 copies per mold |

Color & Finishing |

Color and texture can be customized |

Typical Lead Time |

Up to 20 parts in 15 days or less |