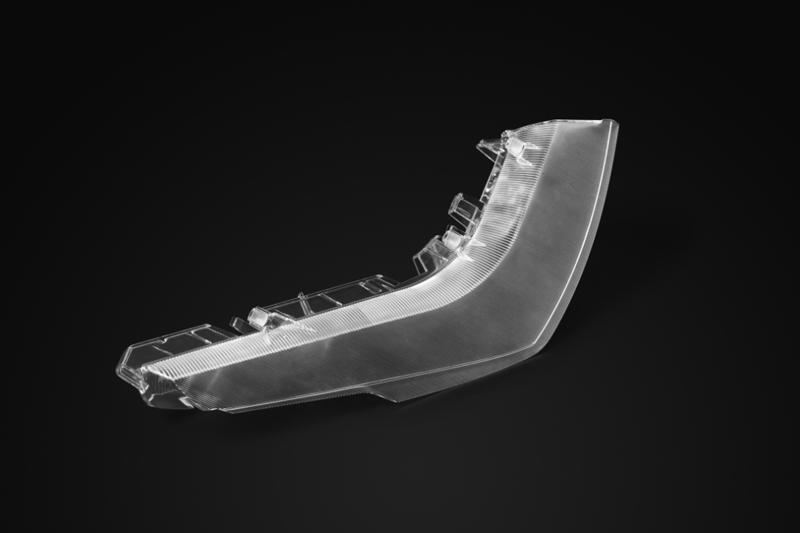

Vacuum Casting Materials

You can choose a wide range of vacuum casting materials depending on the peculiarities of your project. These resins are typically analogs of common plastic materials with comparable performance and appearance. We have grouped our urethane casting materials into general categories to help you make the best decisions for your project.

ABS-Like

Surface Finish for Vacuum Casted Parts

With an extensive array of surface finishes, Breton Precision can create unique surface layers for your vacuum casting parts. These finishes help you meet your products’ appearance, hardness, and chemical resistance requirements. Depending on your material selection and part applications, we can offer the following surface finishes:

|

|

Available Finishing |

Description |

SPI Standard |

Link |

|

|

High Gloss |

Highly reflective surface finish created by polishing the master pattern before mold making. The high-gloss finish offers high transparency useful for cosmetic parts, lenses, and other cleanable surfaces. |

A1, A2, A3 |

|

|

Semi Gloss |

This B grade finish is not highly reflective but offers some sheen. Using gritty sandpaper, you will get smooth, cleanable surfaces between high-gloss and matte. |

B1, B2, B3 |

|

|

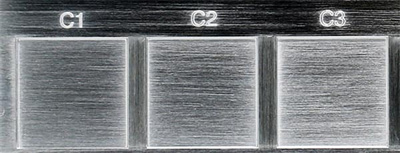

Matte Finish |

Vacuum cast parts will have a satin-like finish through the bead or sand blasting of the master pattern. The C-grade finishes are ideal for high-touch areas and handheld components. |

C1, C2, C3 |

|

|

Custom |

RapidDirect can also provide custom finishes through additional processes. On request, you can get unique secondary finishes for the best results. |

D1, D2, D3 |

Vacuum Casting Tolerances

Breton Precision offers a range of vacuum casting tolerances to meet your custom requirements. Based on the master pattern and part geometry, we can reach dimensional tolerances between 0.2 – 0.4 m. Below are the technical specifications for our vacuum casting services.

Type |

Information |

Accuracy |

Highest precision to reach ±0.05 mm |

Max Part Size |

+/- 0.025 mm +/- 0.001 inch |

Minimum wall thickness |

1.5mm~2.5mm |

Quantities |

20-25 copies per mold |

Color & Finishing |

Color and texture can be customized |

Typical Lead Time |

Up to 20 parts in 15 days or less |