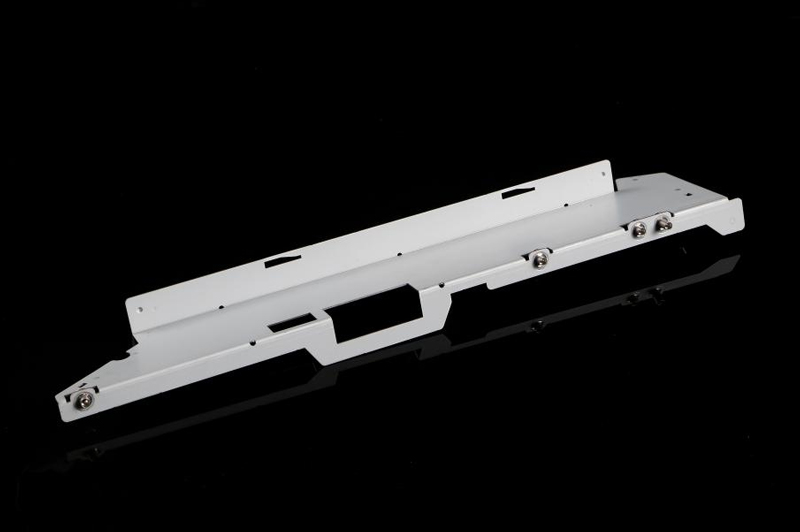

Sheet Metal Fabrication Materials

Our selection of sheet metal materials includes aluminum, brass, stainless steel, and copper,

each enhancing the durability and aesthetics of your metal components.

Copper

Sheet Metal Fabrication Surface Finishing

Opt for different finishes for sheet metal to boost resistance, strength, and visual charm. Should any finishes not be shown on our quote page, just choose ‘Other’ and describe your needs for a personalized fix.

|

Name |

Materials |

Color |

Texture |

Thickness |

|

Anodizing |

Aluminum |

Clear, black, grey, red, blue, gold. |

Smooth, matte finish. |

A thin layer: 5-20 µm |

|

Bead Blasting |

Aluminum, Brass, Stainless Steel, Steel |

None |

Matte |

0.3mm-6mm |

|

Powder Coating |

Aluminum, Brass, Stainless Steel, Steel |

Black, any RAL code or Pantone number |

Gloss or semi-gloss |

5052 Aluminum 0.063″-0.500” |

|

Electroplating |

Aluminum, Brass, Stainless Steel, Steel |

Varies |

Smooth, glossy finish |

30-500 µin |

|

Polishing |

Aluminum, Brass, Stainless Steel, Steel |

N/A |

Glossy |

N/A |

|

Brushing |

Aluminum, Brass, Stainless Steel, Steel |

Varies |

Satin |

N/A |

|

Silkscreen Printing |

Aluminum, Brass, Stainless Steel, Steel |

Varies |

N/A |

< 1 µm |

|

Passivation |

Stainless Steel |

None |

Unchanged |

5μm – 25μm |

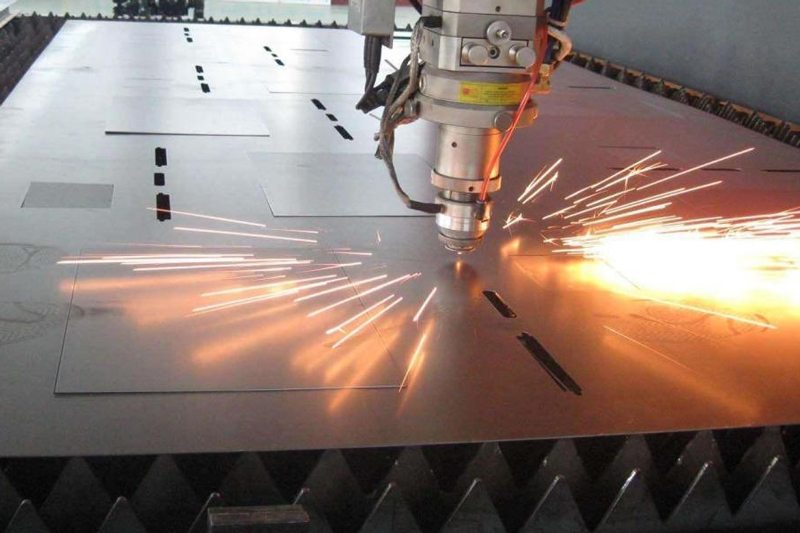

Breton Precision Sheet Metal Processes

Explore the distinct benefits of individual sheet metal methods and locate the ideal fit while placing an order for personalized metal fabrication components.

Process |

Techniques |

Precision |

Applications |

Material Thickness (MT) |

Lead Time |

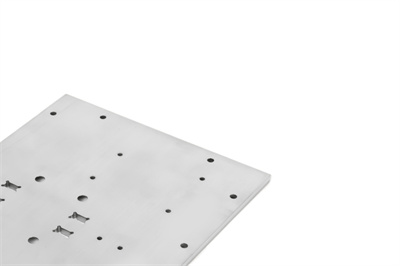

Cutting |

Laser cutting, Plasma cutting |

+/- 0.1mm |

Stock material cutting |

6 mm (¼ inch) or less |

1-2 days |

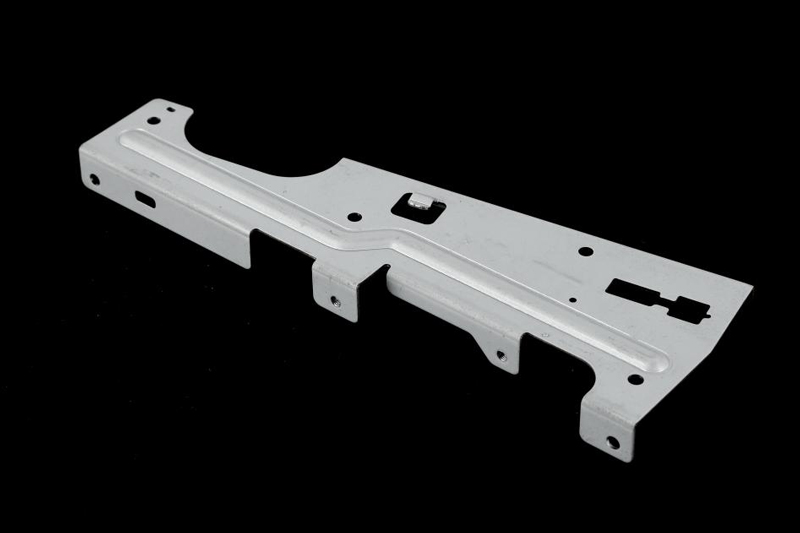

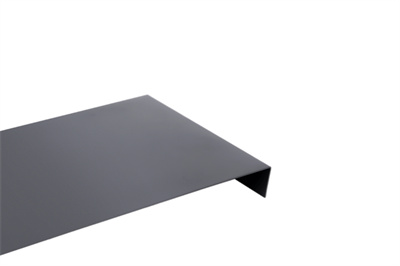

Bending |

Bending |

Single bend: +/- 0.1mm |

Creating forms, pressing grooves, engraving letters, affixing electrostatic guiding tracks, stamping earth symbols, perforating holes, applying compression, adding triangular supports, and additional tasks. |

At least match the sheet thickness with the minimum bend radius. |

1-2 days |

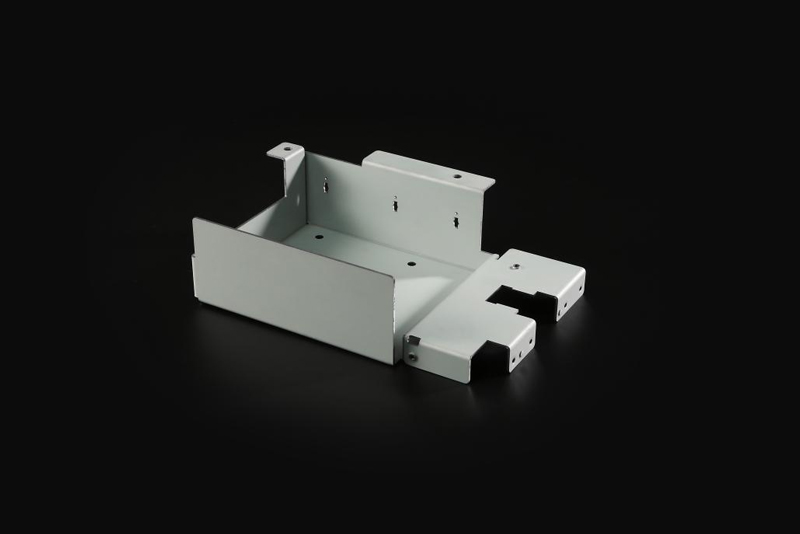

Welding |

Tig Welding, MIG welding, MAG welding, CO2 welding |

+/- 0.2mm |

Manufacturing plane bodies and motor parts. Within vehicle frames, emission networks, and undercarriages. For developing segments in power production and dispersal structures. |

As low as 0.6 mm |

1-2 days |

General Tolerances for Sheet Metal Fabrication

Dimension Detail |

Metric Units |

Imperial Units |

Edge to edge, single surface |

+/- 0.127 mm |

+/- 0.005 in. |

Edge to hole, single surface |

+/- 0.127 mm |

+/- 0.005 in. |

Hole to hole, single surface |

+/- 0.127 mm |

+/- 0.005 in. |

Bend to edge / hole, single surface |

+/- 0.254 mm |

+/- 0.010 in. |

Edge to feature, multiple surface |

+/- 0.762 mm |

+/- 0.030 in. |

Over formed part, multiple surface |

+/- 0.762 mm |

+/- 0.030 in. |

Bend angle |

+/- 1° |

|

As a standard process, sharp corners will be smoothed and polished. If there are specific corners that need to remain sharp, please mark and detail them on your design.