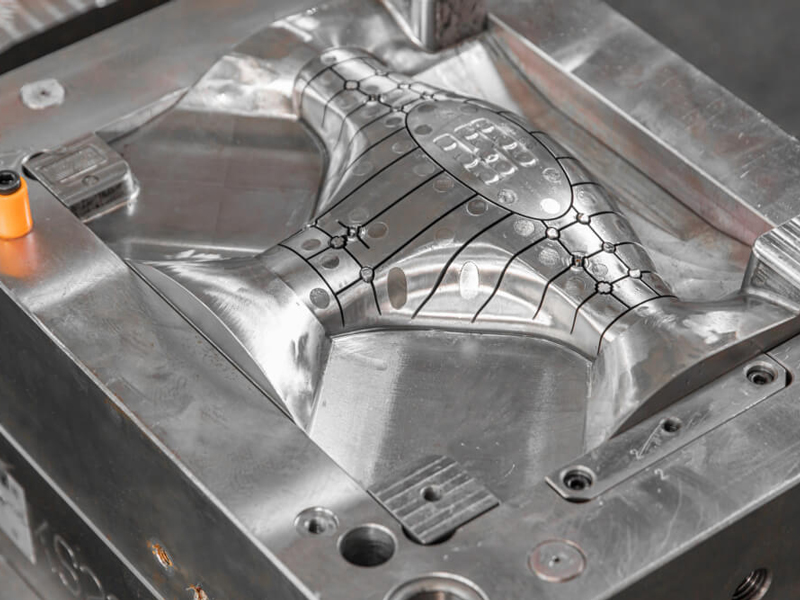

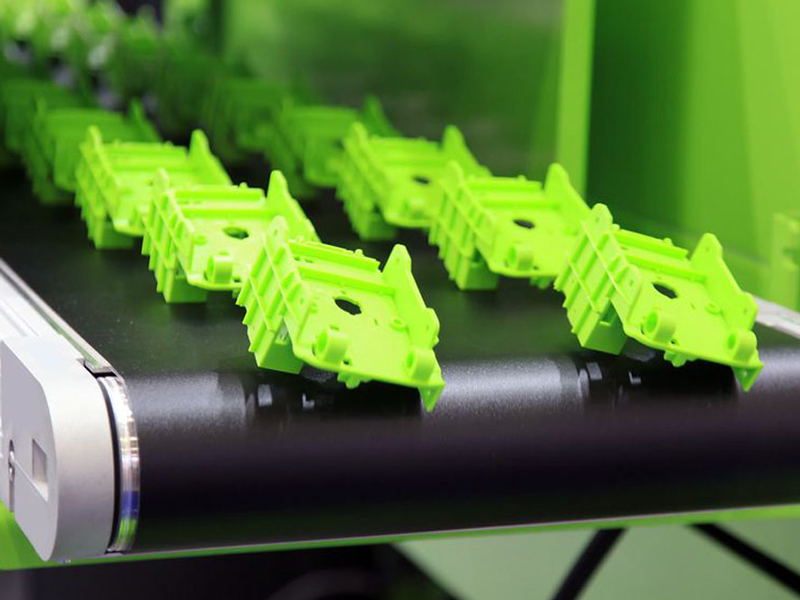

Injection Molding Materials

Breton Precision offers common metals for injection molding tooling, and a variety of popular plastic materials.

Injection Mold Tooling Materials

Thermoplastic

Thermoset

Liquid Silicone Rubber |

Epoxy |

Polyurethane |

Phenolic |

Injection Mold Surface Finishes

We primarily offers SPI finishes for plastic injection molds. For VDI textures, specify your requirements when submitting your quote on our platform.

SPI Finish Standards |

Surface Roughness RA (mm) |

Finishing Method |

Texture |

Steels Recommended |

SPI A1 |

0.012 to 0.025 |

6000 Grit Diamond |

Super High Glossy finish |

S136 (54HRC) or 8407(52HRC) |

SPI A2 |

0.012 to 0.025 |

3000 Grit Diamond |

High Glossy finish |

S136 (54HRC) or 8407(52HRC) |

SPI A3 |

0.05 to 0.10 |

1200 Grit Diamond |

Normal Glossy finish |

S136 (300HB) or 718H |

SPI B1 |

0.05 to 0.10 |

600 Grit Paper |

Fine Semi-glossy finish |

718H |

SPI B2 |

0.10 to 0.15 |

400 Grit Paper |

Medium Semi-glossy finish |

718H |

SPI B3 |

0.28 to 0.32 |

320 Grit Paper |

Normal Semi-glossy finish |

718H |

SPI C1 |

0.35 to 0.40 |

600 Grit Stone |

Fine Matte finish |

718H |

SPI C2 |

0.45 to 0.55 |

400 Grit Stone |

Medium Matte finish |

718H |

SPI C3 |

0.63 to 0.70 |

320 Grit Stone |

Normal Matte finish |

718H |

SPI D1 |

0.80 to 1.00 |

Dry Blast Glass Bead |

Satin Textured finish |

718H |

SPI D2 |

1.00 to 2.80 |

Dry Blast |

Dull Textured finish |

718H |

SPI D3 |

3.20 to 18.0 |

Dry Blast |

Rough Textured finish |

718H |

Classes of Injection Mold

We adhere to the five standard categories of SPI mold classifications from Class 101 to 105, aligning expectations for customers and suppliers alike.

Mold Class |

Production Level |

Cycles |

Applications |

Tolerance |

Cost |

Lead Time |

Class 105 |

Very low |

Less than 500 cycles |

Prototype testing |

± 0.02mm |

Inexpensive to produce a very limited number of product prototypes |

7-10 days |

Class 104 |

Low |

Less than 100K cycles |

Good for limited-production parts with non-abrasive materials |

± 0.02mm |

Fall within low to moderate price ranges |

10-15 days |

Class 103 |

Medium

|

Less than 500K cycles |

For low to medium-production parts |

± 0.02mm |

Fall within common price ranges |

10-15 days |

Class 102 |

Medium to high |

Less than 1M |

Good for parts with abrasive materials and/or tight tolerances |

± 0.02mm |

Fairly high price and made with materials of high quality |

10-15 days |

Class 101 |

Extremely high |

Over 1M cycles |

Extremely high production and fast cycle times |

± 0.02mm |

Highest price and made with only the highest quality materials |

10-18 days |