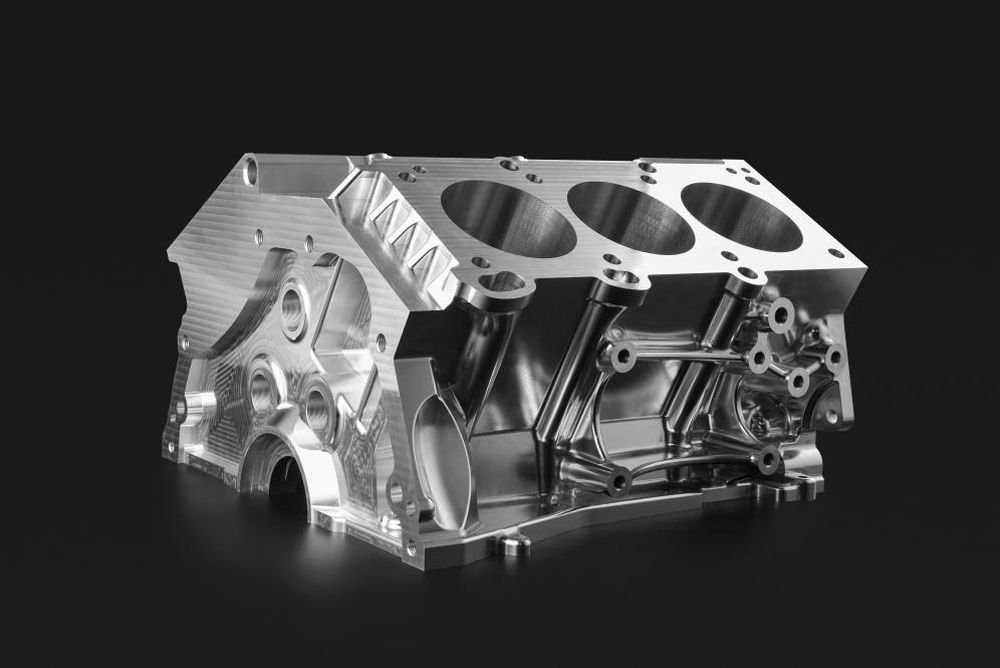

3-Axis, 4-Axis and 5-Axis CNC Machining Centers

Stainless Steel

CNC Machining Tolerances

Our Breton CNC precision machining follows the ISO 2768-m standard for metallic materials and adheres to ISO 2768-c for plastics. When requesting particular tolerances, make sure to specify them clearly on your drawings.

Standards |

CNC Milling |

CNC Turning |

Maximum Part Size |

4000×1500×600 mm 157.5×59.1×23.6 in. |

200×500 mm 7.9×19.7 in. |

Minimum Part Size |

4×4 mm 0.1×0.1 in. |

2×2 mm 0.079×0.079 in. |

Minimum Feature Size |

Φ 0.50 mm Φ 0.00197 in. |

Φ 0.50 mm Φ 0.00197 in. |

Standard Tolerances |

Metals: ISO 2768-m |

Metals: ISO 2768-m |

Linear Dimension |

+/- 0.025 mm |

+/- 0.025 mm |

Hole Diameters |

+/- 0.025 mm |

+/- 0.025 mm |

Shaft Diameters |

+/- 0.025 mm |

+/- 0.025 mm |

Edge Condition |

Sharp corners need to be removed by utilizing bevels or curved edges. Exact measurements for the bevel or radius achieved need to be clearly indicated on the design. |

|

Threads and Tapped Holes |

Diameter: Φ 1.5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter |

Diameter: Φ 1.5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter |

Breton Precision can produce threads of any specification and size required by our customers. | ||

Text |

Minimum width of 0.5 mm, depth of 0.1 mm Breton Precision can utilize CNC marking or laser marking to produce standard text as per customer requirements. |

Breton Precision has the ability to utilize laser engraving to create standard text on components manufactured by CNC machining. |

Lead Time |

7 business days |

7 business days |